OVERVIEW

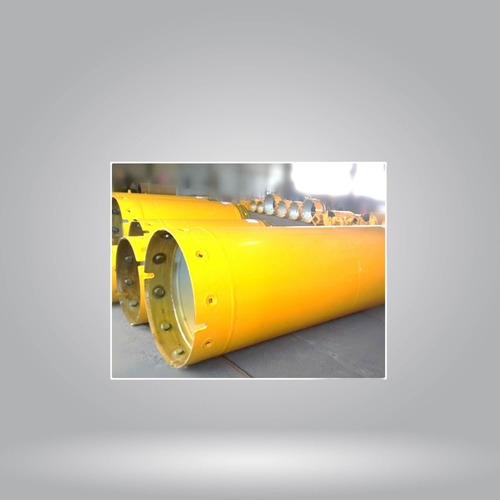

CASING

Jilani Engineering Works, manufactures casing systems used in piling construction works as per customer requirements for their projects. We manufacture both types of casing systems, single & double walled casings used in piling construction works.

PRODUCT BROCHURE PRODUCT ENQUIRYTypes of Casing

SINGLE WALLED CASINGS FOR PILING CONSTRUCTION

Single-walled casings are also commonly used in piling construction, and they serve a similar purpose as double-walled casings, but they consist of only one layer of steel.

Single-walled casings are used to support the sides of a borehole during drilling, preventing soil or water from collapsing into the hole. They are commonly employed in various foundation and piling applications.

Similar to double-walled casings, single-walled casings are typically made of steel. The choice of steel grade and thickness depends on the specific requirements of the construction project.

During the drilling process, the single-walled casing is used to stabilize the borehole and prevent it from collapsing. After reaching the desired depth, concrete is poured into the borehole through the center of the casing to form the pile or foundation.

| Diameter | Length |

Casing-wall

Thickness-1 |

Casing-wall

Thickness-1 |

Bolt

QTY |

|||||

|---|---|---|---|---|---|---|---|---|---|

| D1/D2 | 1m | 2m | 3m | 4m | 5m | 6m | a1 | a2 | bolts |

| (mm) | Weight(kg) | (mm) | (mm) | (nos) | |||||

| 1300/1200 | 845 | 1475 | 2105 | 2735 | 3365 | 3995 | 20 | 40 | 12 |

| 1500/1400 | 1310 | 2220 | 3130 | 4040 | 4950 | 5860 | 25 | 50 | 12 |

| 1800/1700 | 1580 | 2675 | 3770 | 4865 | 5960 | 7055 | 25 | 50 | 16 |

| 2000/1880 | 2140 | 3355 | 4570 | 5785 | 7000 | 8215 | 25 | 50 | 16 |

| 2200/2080 | 2350 | 3690 | 5030 | 6370 | 7710 | 9050 | 25 | 60 | 16 |

| 2500/2380 | 2575 | 4100 | 5625 | 7150 | 8675 | 10200 | 25 | 60 | 16 |

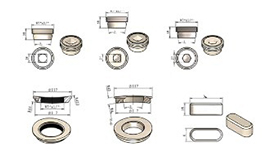

DOUBLE WALLED CASINGS FOR PILING CONSTRUCTION

Double-walled casings play a crucial role in piling construction, particularly in situations where ground stability must be maintained during the drilling process. These casings are used to prevent soil or water from collapsing into the borehole and to maintain the integrity of the hole until the concrete is placed.

Double-walled casings are primarily used to create a stable borehole during drilling for foundations, piles, or diaphragm walls. The outer casing prevents soil or water from collapsing into the hole, while the inner casing provides support for the concrete during placement. These casings are typically made of steel to provide the necessary strength and durability. The outer and inner casings are designed to fit together, forming a double-walled structure.

The drilling process involves using the double-walled casing to maintain the integrity of the borehole as it penetrates the ground. Once the desired depth is reached, concrete is poured through the inner casing to form the pile or foundation.

Double-walled casings come in various sizes and specifications depending on the requirements of the construction project. The diameter and thickness of the casings are determined by factors such as soil conditions, load-bearing capacity, and design specifications.

| Diameter | Length |

Casing-wall

Thickness- 1 |

Casing-wall

Thickness -1 |

Total

Thickness |

Bolt

QTY |

|||||

|---|---|---|---|---|---|---|---|---|---|---|

| D1/D2 | 1m | 2m | 3m | 4m | 5m | 6m | a1 | a2 | t2 | bolts |

| (mm) | Weight(kg) | (mm) | (mm) | (mm) | (nos) | |||||

| 620/540 | 403 | 739 | 1074 | 1411 | 1747 | 2081 | 12 | 8 | 40 | 8 |

| 750/670 | 492 | 902 | 1311 | 1722 | 2131 | 2540 | 12 | 8 | 40 | 10 |

| 880/800 | 585 | 1069 | 1552 | 2036 | 2520 | 3005 | 12 | 8 | 40 | 10 |

| 1000/920 | 669 | 1221 | 1773 | 2328 | 2877 | 3429 | 12 | 8 | 40 | 10 |

| 1180/1100 | 844 | 1580 | 2316 | 3052 | 3787 | 4522 | 16 | 8 | 40 | 12 |

| 1200/1120 | 872 | 1620 | 2370 | 3120 | 3870 | 4620 | 16 | 8 | 40 | 12 |

| 1300/1220 | 933 | 1746 | 2558 | 3372 | 4184 | 4996 | 16 | 8 | 40 | 12 |

| 1500/1400 | 1433 | 2628 | 3817 | 5009 | 6210 | 7393 | 20 | 10 | 50 | 12 |

| 1800/1700 | 1730 | 3166 | 4602 | 6038 | 7474 | 8910 | 20 | 10 | 50 | 16 |

| 2000/1880 | 2450 | 4280 | 6110 | 7940 | 9770 | 11600 | 20 | 15 | 60 | 16 |

| 2200/2080 | 2700 | 4720 | 6740 | 8760 | 10780 | 12800 | 20 | 15 | 60 | 16 |

| 2500/2380 | 2960 | 5240 | 7520 | 9800 | 12080 | 14360 | 20 | 15 | 60 | 16 |

.jpg)